“Shree Coatings” – Electrophoretic Lacquers (EPL) provide you with Excellent Gloss/ Matt, Extreme durability, Good adhesion and performance. Our EPL System replaces Plating finishes and can be directly applied to metals. It helps you to take a step towards maintaining an Eco-friendly Environment. EPL relies on the migration and deposition of charged particles from a solution onto an opposite-polarity substrate (workpiece) under the application of an external power supply. These are water-based Coatings and can easily be applied on metals such as Aluminium, Zinc Brass, Stainless Steel, Iron, and Alloys. It Forms a Unique and labeled Coating on your products. “Shree Coatings” EPL provides you with a wide range of finishes such as Colour Shades, Clear finishes, Matt finishes, Satin finishes, Texture finishes, etc.

Electrophoretic Lacquers

EPL & CED Coating (Electro Phoretic Lacquers) as:

Solvents

-

P.U. Thinner 1621

Price on Query -

Catalysed Thinner 705, 705 A/F, 805

Price on Query -

Brass Thinner 722, 723, 724, 724(P)

Price on Query

Electrophoretic Lacquers (EPL) Process

1. Rinse your product three times in distilled water. Don’t forget to wear your safety equipment.

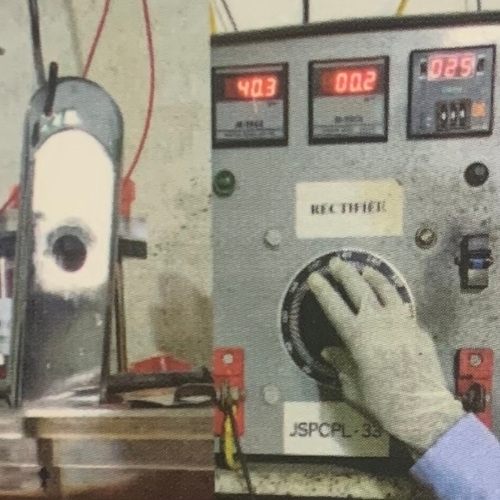

2. After Rinsing, take your product Shree Coating EPL tank, now by using a rectifier, provide 50-60V for 20-30 seconds.

3. Rinse the times again in distilled water. Let force product for three dry/pre oven for that water evaporates completely from 10-15 minutes so the surface.

4. Place the product in the oven and maintain a temperature of 120-140 C for the time period of 30-35 minutes

5. After the time period, your product is coated with the finish provided by Shree Coatings.

Equipment Needed

1. Main tank

2. Washing tank

3. Ultra filter

4. Cartridge filter

5. Rectifier

6. Oven